ONLINE MONITORING SYSTEM FOR WEAVING

Looms | Preparatory | Processing | Fabric Inspection

Monitor Performance & Enhance Productivity using DATALOG

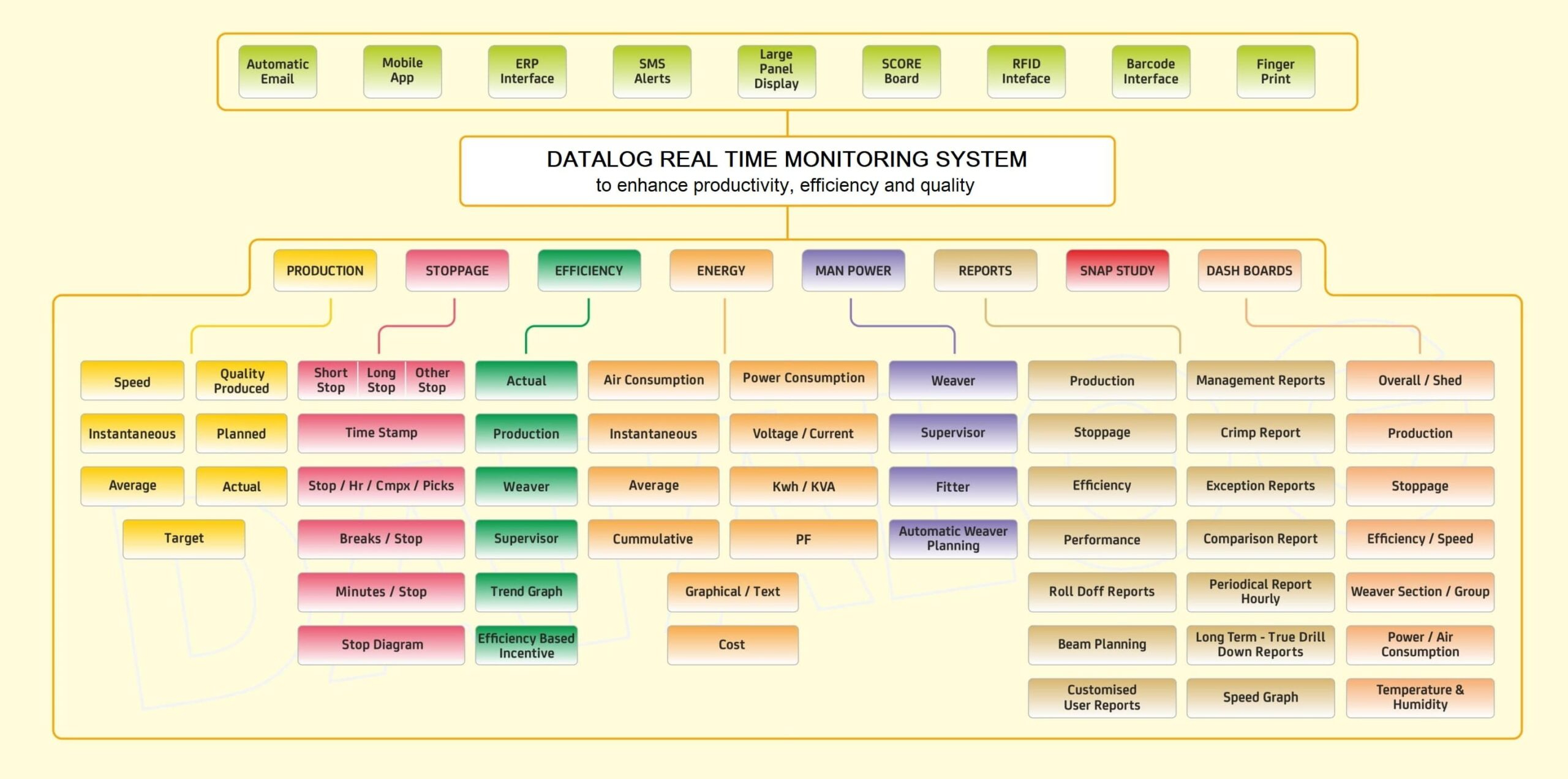

Productivity is ensured by the continuous operation of each loom in the weaving mill. Unwanted stoppages can throw a spanner in the works and drastically impact production schedules. That is why it is imperative to invest in Datalog online loom data monitoring system for weaving looms to monitor the weaving shed 24 X 7.

Datalog Online Monitoring system facilitates continuous monitoring of each loom individually and collectively. Data is processed and useful reports are generated in the web-based software, which enables seamless operations, and contributes to better productivity, which translates into higher profits.

Products Range of DATALOG On Line Monitoring System for Weaving

- Looms (Any Type / Any Make / Any Model / Manufacturing Any Product)

- Weaving Preparatory (Warping, Sizing, Beaming)

- Processing (Dyeing, Finishing, etc.,)

- Fabric Inspection System

Products Options of DATALOG On Line Monitoring System for Weaving

- Production, Stoppage & Efficiency (Machine Wise)

- Air Consumption (Machine wise, Group Wise, Line Wise, at Compressor) - Optional

- Power (Machine Wise, DB wise, SSB Wise, Lighting Load Wise, at Power House, Humidification Plant, Compressor) - Optional

- Humidity & Temperature (At various points inside the shed) - Optional

- Spare Parts Failure Analysis (Machine Wise)

BENEFITS OF DATALOG ONLINE MONITORING SYSTEM FOR WEAVING

- Integrated information about all types of looms in one software

- Provision for viewing all information about the machine at the machine terminal installed in each loom

- The reason for the long stop can be entered into the machine terminal on the loom

- Web-based software & hence easy to access the data from within or outside the mill (during travel)

- The mobile version of the software is available

- Automatic Weaver Planning

- Minimize machine downtime with continuous monitoring

Continuous monitoring of Breaks per Hour & Minutes per Stop for Warp, Weft, and other stops - Compare machines running with the same style to identify low-performing machines and fine-tune

- Compare weavers to identify low-performing weavers and train for better results

- Efficiency Trend Graph to analyse Loom behaviour and fine-tune for better efficiency

- The stop diagram allows to improve performance of the loom by detecting repeated stops, and too many stops.

- Exception Reports can be called for any parameter to analyse the weak areas

- Snap study on every parameter

- Macro to Micro Analysis of any parameter can be called for long-term analysis (Year – Month – Day)

- Easy Interface with any ERP/SAP

- Beam planning reports, and unassigned beam reports are available

- Roll doff reports, and crimp reports are available

- The CFM of each loom is continuously monitored to provide instantaneous CFM, average CFM, cumulative CFM, and CFM/meter of fabric produced

- Air consumption report in text and graph for loom-wise, shift-wise, style-wise, and shed-wise

- By tracking CFM consumption – you can analyze the cost per meter

- Optimize speed vs CFM consumed

- Prevent avoidable stoppages/breakdowns

Analyzing power consumption reports can help mills to

- Reducing electricity bills (cost)

- Arriving at cost/meter of manufactured fabric

- Speed vs power consumption

- Quality of power

- Monitor the health of the motor and other related hardware

- Analyse RH & Temp. variations at different points inside the shed

- Optimise RH & Temp. for best Shed Running Condition

Machine Terminal (Standard Model) for Production Monitoring with 6 Inputs for Picks, Warp, Weft, Leno, Selvedge, Catchchord)

Machine Terminal with 18 Stops for automatic registering of 17 Stops reasons from machine panel

Stop Code Entry Terminal for Entering Stop Reason at one place

Machine Terminal with Finger Print Sensor for Registering Operator ID / Attendance, Supervisor ID / Attendance, Inspector ID, Stop Code Entry

Machine Terminal with Bar-Code Interface or RFID Interface for Registering, Style, Operator ID / Attendance, Supervisor ID / Attendance, Inspector ID, Stop Code Entry

Machine Terminal with Fabric Defect Entry for Registering Fabric Defect on the Loom

Machine Terminal with Roll Doff – Automatic Roll Doff on prefixed Picks / Meter

Machine Terminal with Automatic Looms Start / Stop arrangement – Stop the Loom for any pre-set setting by the mills for Standard / Deviation

Machine Terminal with Lamp Post Indication Arrangement to provide various Indications for any pre-set setting by the mills for Standard / Deviation

Score Board in 3 Sizes – For every Loom / Machine, For Group of Looms, For Shed or Central Location

SMS / Email for automatic Alerts / Reports

LCD TV Software at Central Locations inside the Shed / Supervisor, Office Room

Machine Terminal with Touch Screen Model Panel on Loom

Salient Features

- On Line Monitoring of all Looms 24 X 7 for Production, Stoppage & Efficiency

- Air Consumption and Power Consumption can be monitored(Optional)

- Temperature and Humidity of the Loom Shed can be monitored at different locations(Optional)

- On Loom Fabric Inspection System (Optional)

- Integrated information covering all looms on a single computer

- Can be installed on all types of looms (Airjet, Waterjet, Projectile, Rapier, etc.,)

- Can be installed looms manufacturing any type of fabric (Grey, Sheeting, Shirting, Terry Towels, Carpets, etc.,)

- Viewing of all Information on the Machine through the Machine Terminal fitted on each Loom

- System automatically Records all loom stops with time stamp

- Warp, Weft, Leno, Selvedge stops are recorded with reason automatically by the system

- Reason for Long Stop can be entered on the Machine Terminal

- Continuous monitoring of Actual (A%) and Production / Weaver (P%) Efficiency

- Automatic Weaver Planning

- Spare Parts failure analysis

- Roll / Label printing on completion of Fabric Roll on the loom(Optional)

- Roll Doff Indication / Stop the loom on arrival of a Roll based on Picks / Meters produced(Optional)

Benefits

- Reduced Machine Down Time

- Increased efficiency and Production

- Optimized production schedules

- Improvement in Operator Work Load

- Decrease in Power Cost by better Power Utilization

- Compare machines running with same product Style / Design

- Identify weak points and weak areas

- Reduces administration Work

- Bring low performing machine seperately for improvement

- Optimize Speed vs. Power Consumption

- Optimize Production vs Cost (Units Per Meter)

- Optimize Speed / Production vs Air Consumption

- Improved product compliance

- Quality improvement

- Prevent Avoidable Stops / Breakdowns

- Monitor Health of Motor

- Identify Mechanical Alignments, Drive shaft / Bearing / Lubrication problems

- Continuous monitoring of Quality of Power

- Forewarn deteriorating points before it is too late

- Fine-tuning Maintenance Practice and Schedules

Do you want to Know more about . . .

Online Monitoring System for Loom

Weaving preparatory and processing

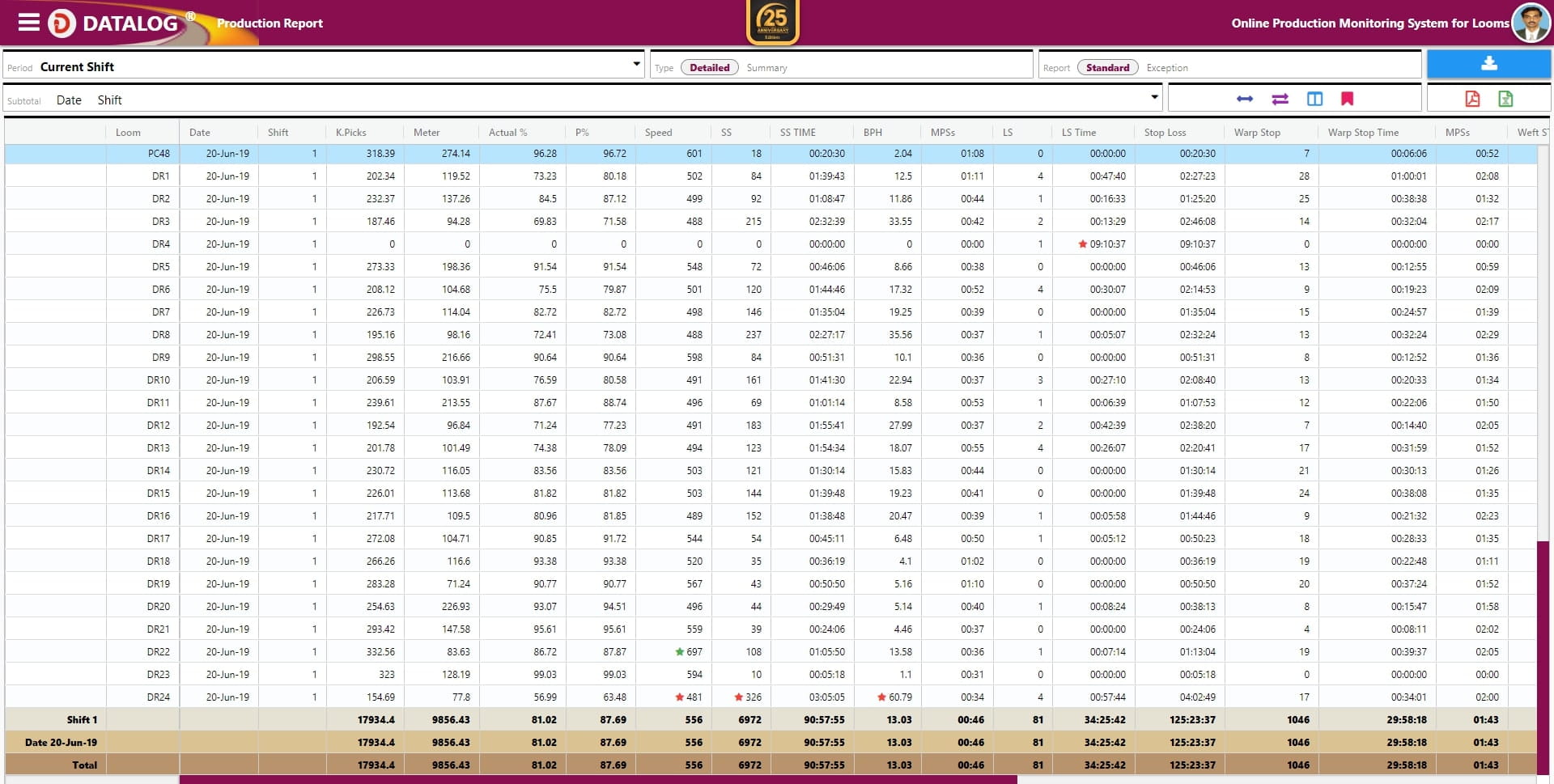

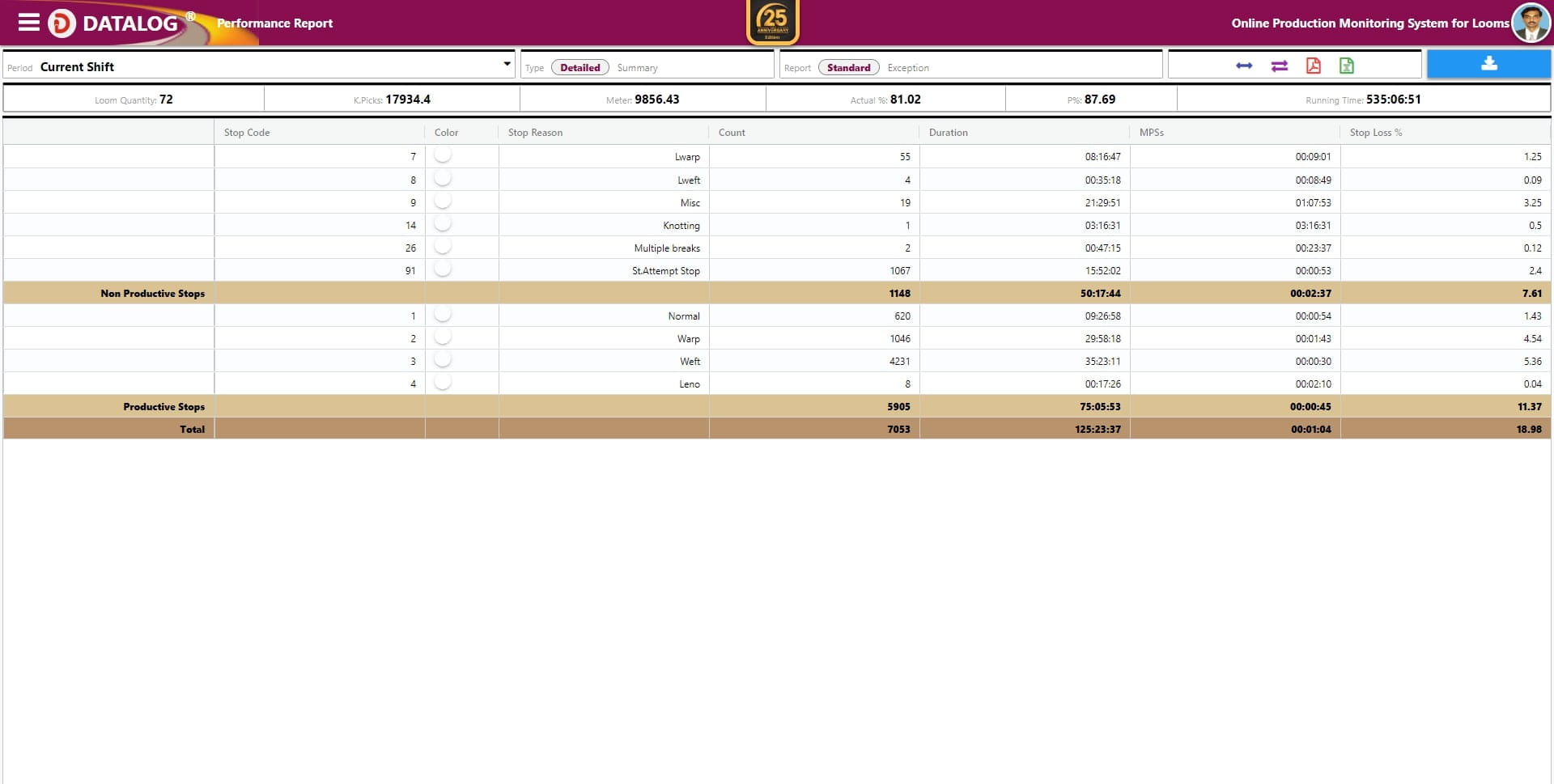

REPORTS, GRAPHS AND SCREENS

- General Reports

- Management Reports

- Comparison Reports

- Periodical Reports

- Power Graph & Reports

- Air Consumption-Graph & Reports

- Special Reports

- Production I Stoppage | Efficiency

- Efficiency Trend | Stop Graph

- True Drill Down Long Term Reports (From Macro to Micro Level)

- Efficiency Trend Graphs of Year, Month, Day

- All Reports can viewed by Machine I Style I Weaver I Supervisor I Department

- Assigned Men

- Snap study

- Exception reports

- Stop Bar Graph to show Machine Running / Stop over a selected period

- Speed graph

- Roll doff reports

- Beam planning and unassigned beam reports

- Crimp report

- Performance report

- Long-term report

- Monthly report

- User reports

- Weavers comparison

- Supervisor comparison

- Loom comparison

- Style comparison

- Weekly reports

- Monthly reports

- Hourly reports

- Two/Three shift reports

- Power consumption

- Voltage

- Current

- Power factor

- Frequency

- Instantaneous CFM report

- Average CFM

- Cumulative CFM

- Meter/KG report

- Temperature and humidity graph & report

- Fabric defect report