Online Monitoring System For KNITTING

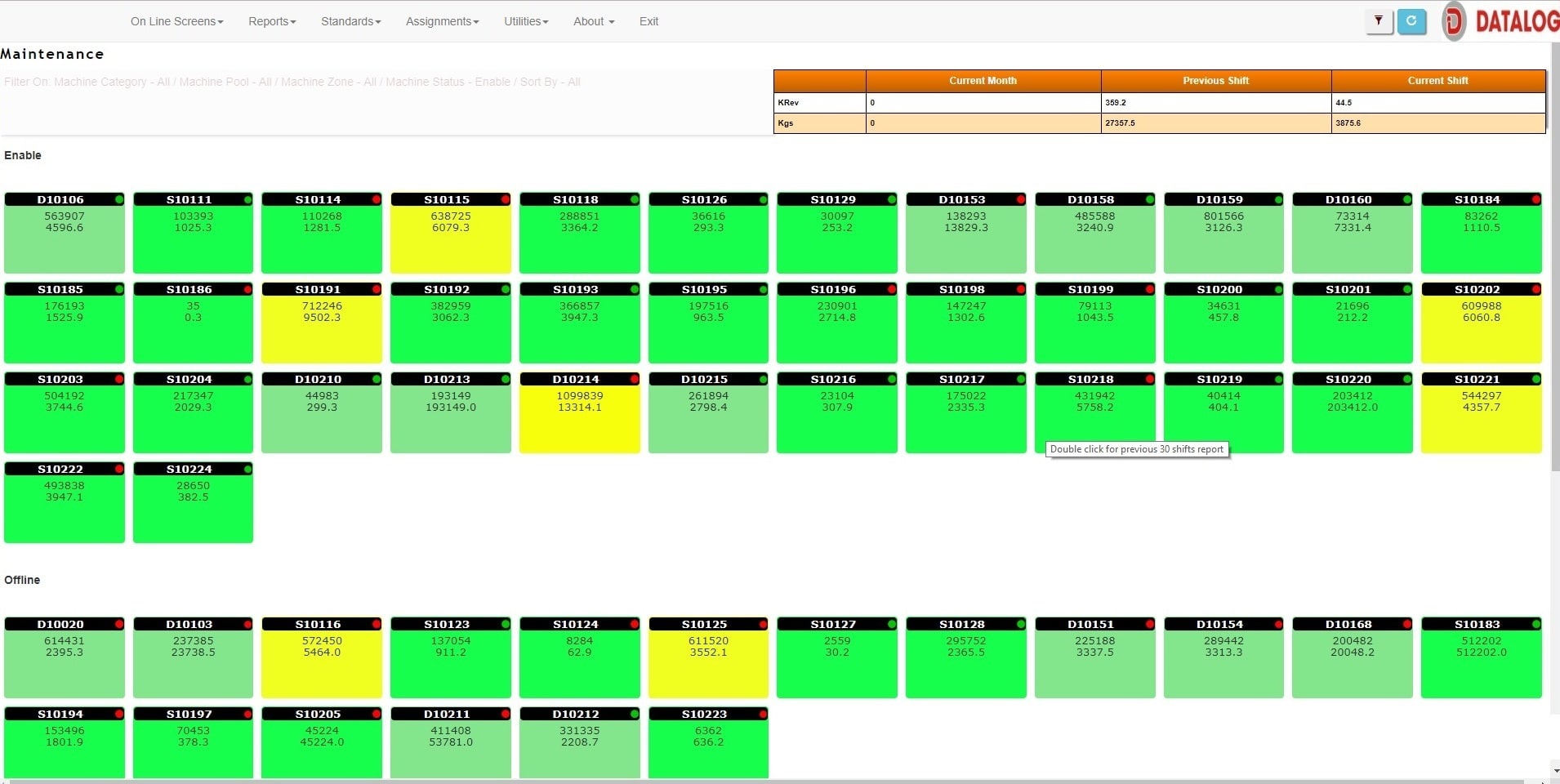

The Datalog Online Monitoring System for Knitting helps in seamless running of the knitting operation and contributes to better productivity. Datalog Online Monitoring System for knitting facilitates continuous monitoring of each machine. Various parameters like weight and the length of the knitted fabric can be had at the click of a button. The knitting performance can be significantly enhanced.

Products Range of Datalog Online Monitoring System for Knitting Available for machines of Any Type, Any Make, Any Model, Manufacturing Any Product.

Benefits of DATALOG OnLine Monitoring System for Knitting

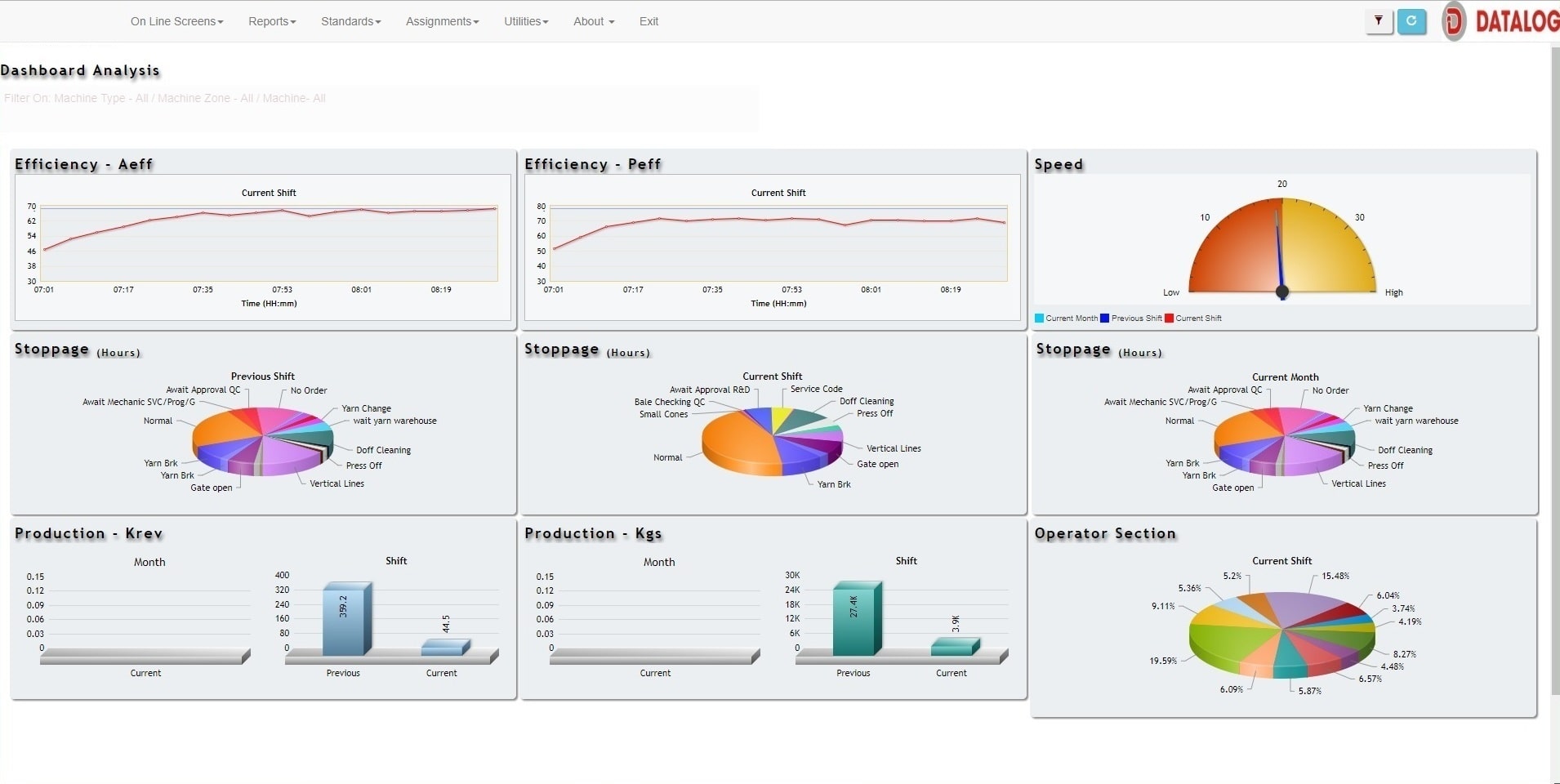

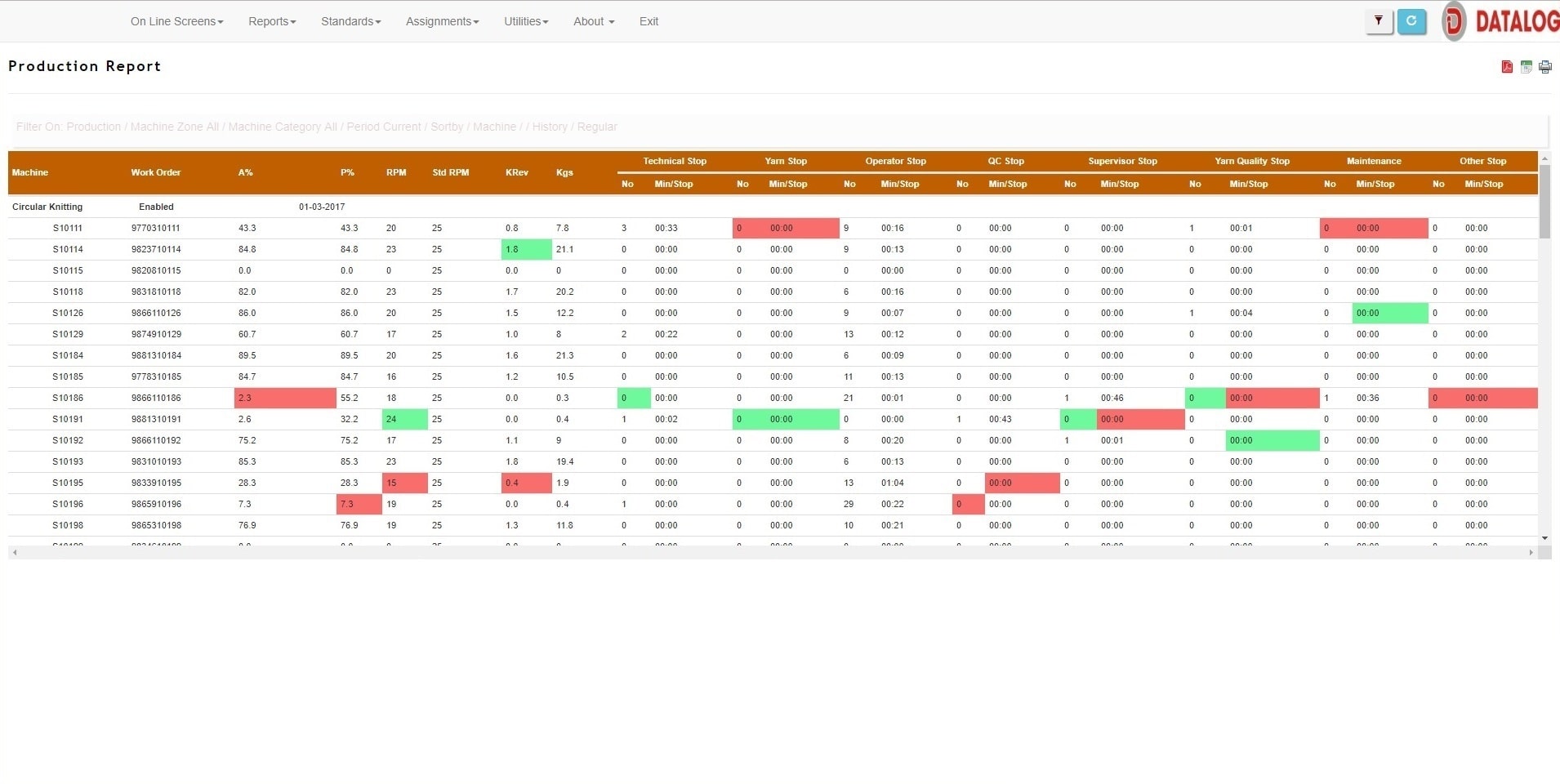

Production, Stoppage & Efficiency Monitoring

- Integrated information of all types of looms in one software

- Provision to view all information on Machine Terminal fitted on every Loom

- Long Stop reason can be entered on the loom

- Web based software & hence easy to access the data from within or outside the textile mill (during travel)

- Mobile Version of Software available

- Automatic Weaver Planning

- Reduce Machine Down Time by continuous monitoring

- Continuous Monitoring of Breaks per Hour & Minutes per Stop for Warp, Weft and other stops

- Compare Machines running with same Style to identify low performing machine and finetune

- Compare Weavers to identify low performing weaver and train for better result

- Efficiency Trend Graph to analyse Loom behaviour and finetune for better Efficiency

- Stop Diagram to find out repeated stops, too many stops and finetune the Loom

- Bring Low performing Loom at par with the best

- Exception Reports can be called for any parameter to analyse the weak areas

- Snap Study on every parameter

- Macro to Micro Analysis of any parameter can be called for long term analysis (Year – Month – Day)

- Easy Interface with any ERP

- Beam Planning Reports, Un Assigned Beam Reports are available

- Roll Doff Reports are available

- Crimp Reports are available

Air Consumption Monitoring

- CFM of each Loom is monitored continuously to provide

- Instantaneous CFM

- Average CFM

- Cumulative CFM

- CFM / Meter of fabric produced

- Air Consumption Report in Text & Graph for

- Loom Wise

- Shift Wise

- Style Wise

- Shed Wise

- By Monitoring CFM Consumed – Cost per Meter can be analysed

- Optimise Speed vs CFM consumed

- Prevent Avoidable stops / Breakdowns

Power Monitoring

- Reduce Power Bills (Cost)

- Arrive at Cost / Meter of fabric produced

- Speed vs Power Consumed

- Quality of Power

- Monitor Health of Motor and other related hardware

Humidity & Temperature Monitoring

- Analyse RH & Temp. variations at different points inside the shed

- Optimise RH & Temp. for best Shed Running Condition

Salient Features

- Integrated information solutions covering all types of Machines

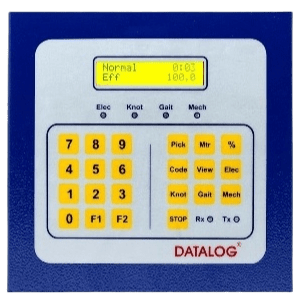

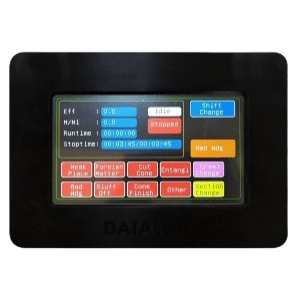

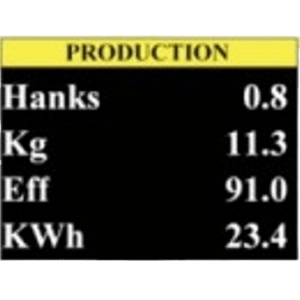

- Viewing of Production, Stoppage, Efficiency & Speed Information on the machine

- Various reports on Production, Stoppage, Efficiency, etc.,

- Order Planning and Yarn consumption reports

- Performance reports forTop Level Management

- Snap Study on Running / Stopped machines

- Exception reports on Efficiency, Production & Stoppage limits

- Easy identification of Efficiency of the machines in different colours

- Various Graphical reports

- Efficiency Trend Graph for a Shift, Day

- Modular design & hence easy to add new machines

- ERP Interface / Excel Transfer

Models & Optional Attachments