FABRIC INSPECTION SYSTEM

Datalog – Fabric Inspection System is a Web Based system equipped with state of art Micro Controller based Fabric Inspection Terminal(FIT) with Touch Screen Display / User Specific Keyboard that replaces the conventional way of manual recording.

- Inspector with ease can enter Fabric Defects & Points on the Fabric Inspection Terminal(FIT) by gently pressing the pre-defined Defect & Points.

- The system automatically measures & records Fabric Length at which the Defect & Point has occurred using the Shaft encoder connected to Fabric Inspection Terminal.

- A computer connected in network collects information recorded by inspector on FIT through wireless technology.

- Web Based Software processes these data from the FIT.

- Process includes Capturing, Sorting, Storing, Retrieving, Calculating and Displaying various User friendly Reports & Screens.

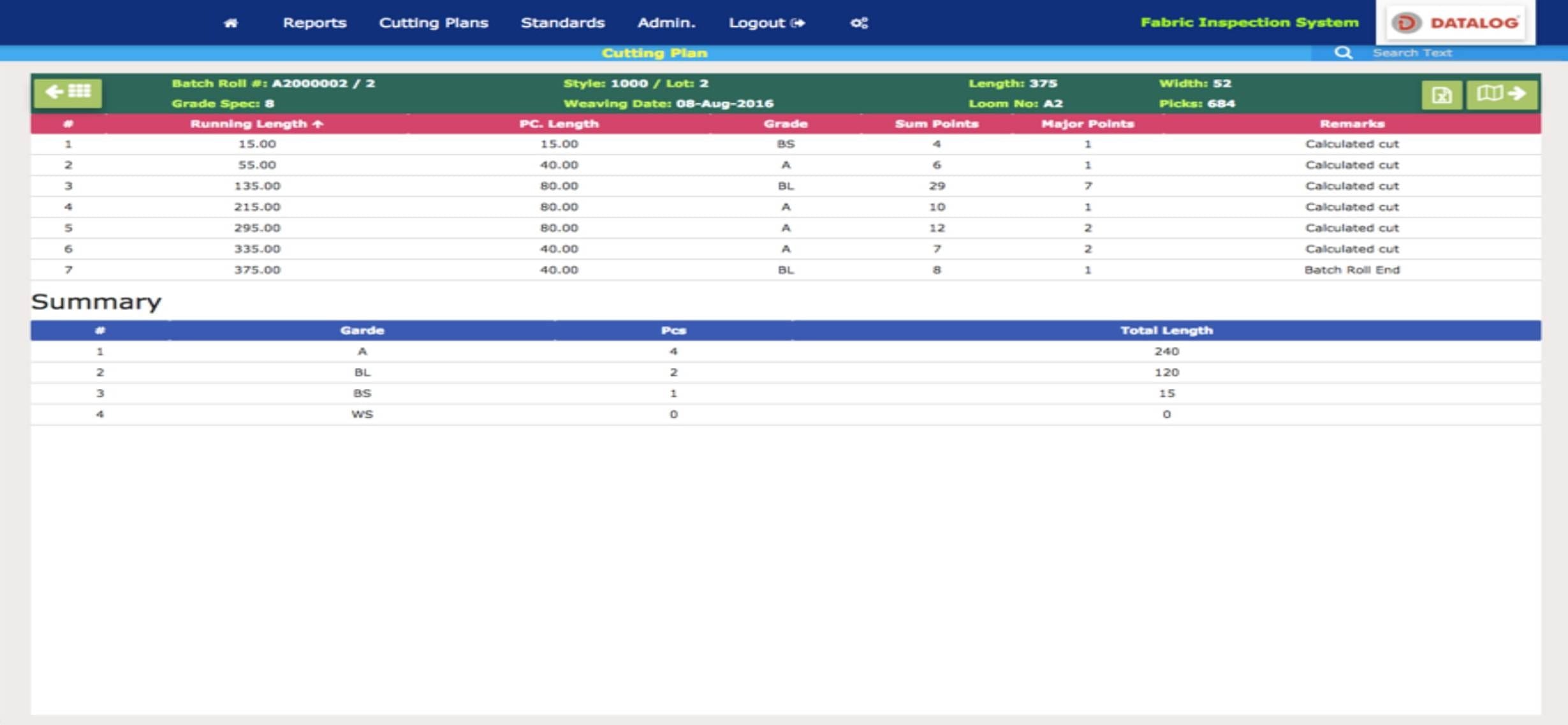

- This software is also designed with an unique artificial intelligent logic to generate Automatic Cutting Plan to achieve maximumpossible realization from inspected fabric based grading specifications defined by textile mills.

- Automatic Cutting Plan is displayed in Graph and Text

- Software comes with inbuilt reports for Monitoring Productivity, Realization and Defect Analysis.

- Customised reports can be generated.

- Users can access these information through web browser based on their access levels from remote locations.

- System also allows multiple users to access data simultaneously.

- System can automatically use different Grading Standard for Different Buyer.

Benefits

- Paperless since Data is being stored on Fabric Inspection Terminal/ Computer

- Error Free recording since entry is on User Specific design

- Fabric Length is measured automatically using Shaft Encoder and hence 100% accuracy.

- Point of Defect Occurrence is accurate since length is measured using Shaft Encoder

- Graphical view of Defect Mapping is generated from system and hence easy for decision making

- Fabric Classification (Grading of Rolls) is done automatically by system and hence laborious process of Manual Gradingcan be avoided

- Automatic Cutting Plan is available from system at the end of a Master Batch Roll in Graph & Text and hence easy to make Rolls

- Inbuilt Productivity Reports

- Inbuilt Realisation Reports

- Inbuilt Defect Analysis Reports

- Reports are in drill-down form, Starts from overview to the deep-root to enable easy and meaningful analysis for the users

- Easy to Train & Operate

- Assisted Cutting Terminal - To install the system on Cutting Table to stop the Machine as per the cutting plan

- Provision for ERP Interface

Salient Features

- Defect Codes can be customized as per mill requirement using colour and symbol

- Defect Keys can be Grouped and Coloured as per mill requirement

- Defect Keys can be Positioned as per mill requirement on FIT

- Classification of defects with respect to Department available (Weaving Defects, Sizing Defects, etc.,)

- Fabric Width can be entered at periodical intervals

- Flags can be marked on the FIT during inspection

- Long Defects can be entered on the FIT

- Horizontal Defect Position can be entered on the FIT

- Recording of Batch Ends / Roll Ends.

- Option to enter Manual Roll / Piece Cutting by the Inspector

- Easy to access from anywhere as software is Web - Based

- Defect Map with Zoom in / out facility

Optional

- Label Printing for each Roll in Text / Barcode

- Barcode scanner interface for capturing Batch Roll information

- Weighing Scale interface for Roll weight

- Audio / Video Indication alerts for the operator